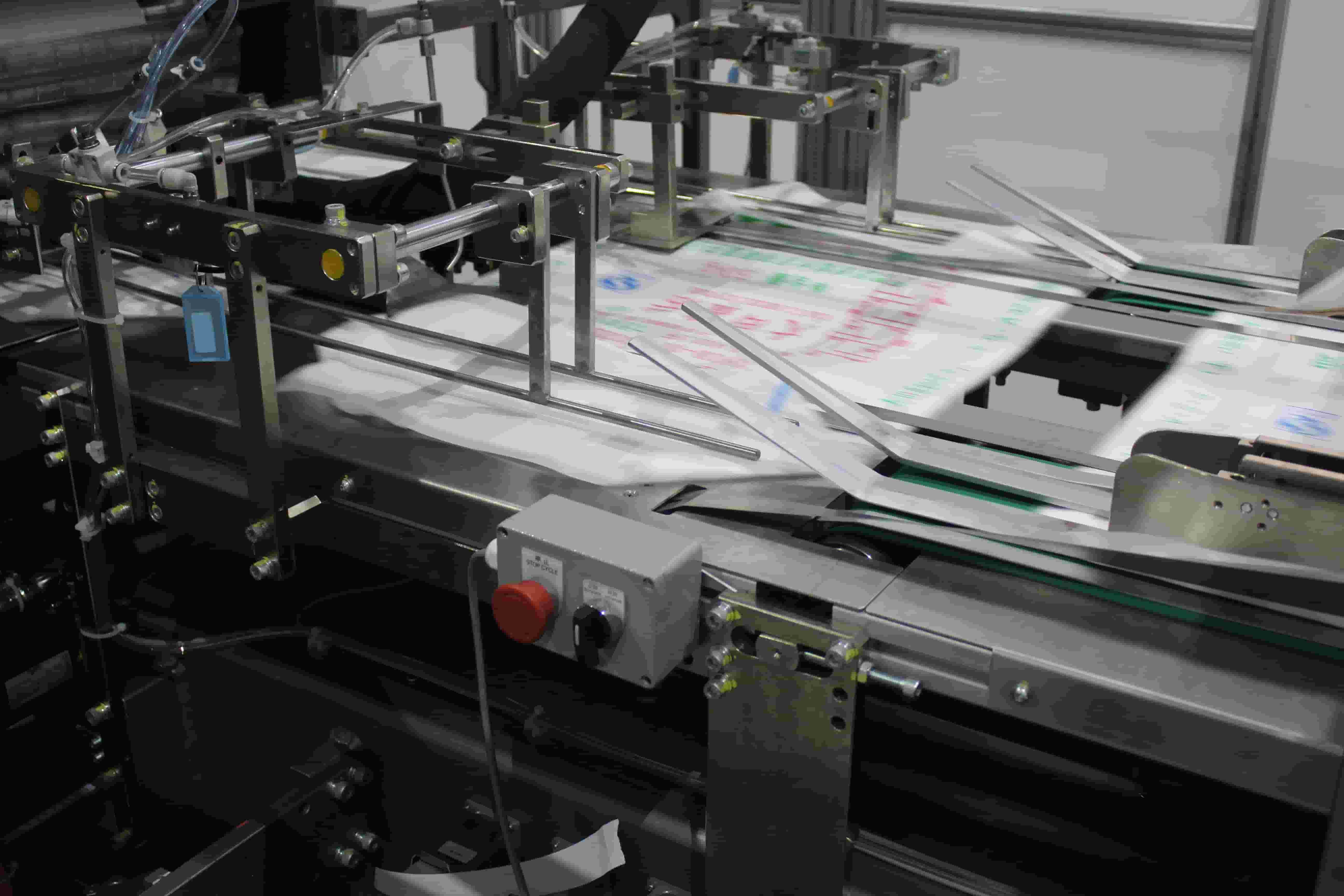

Máquina de fabricação de saco de válvulas para PE/PP/Saco composto de Plástica de Papel

Na indústria de embalagens, os sacos de válvula de tecido plástico são amplamente utilizados em cimento, químico, grãos e outros campos devido à sua durabilidade, alta capacidade de carga e características de proteção ambiental.

Nome do produto :

Valve bag making machine for PE/PP/Paper-plastic composite bagItem nº :

GC-850-6SPedido (quantidade mínima) :

1Pagamento :

30% advance payment, 70% balance before shipment or negotiableOrigem do Produto :

xiamen,chinaPorto de embarque :

XIAMEN or Or according to your needsTempo de espera :

3 monthsMáquina de fabricação de saco de válvulas para PE/PP/Saco composto de Plástica de Papel

Na indústria de embalagens, os sacos de válvula de tecido plástico são amplamente utilizados em cimento, químico, grãos e outros campos devido à sua durabilidade, alta capacidade de carga e características de proteção ambiental. FK008-ⅲ A máquina de fazer bolsas de bolsa de válvula de plástico totalmente automática tornou-se o equipamento preferido para fabricação eficiente de bolsas, com sua tecnologia patenteada desenvolvida de forma independente, configuração internacional de primeira linha e processo de produção inteligente. Seja uma bolsa de fundo quadrado revestido com uma camada única ou requisitos de impressão de alta precisão, esta máquina automática de fabricação de bolsa de tecido PP pode gerar de forma estável a uma velocidade de 110-130 por minuto, ajudando as empresas a reduzir custos e aumentar a eficiência.

Vantagens principais

1. Tecnologia patenteada, eficiente e estável

Tecnologia de abertura de bolsas triangulares: design patenteado de forma independente, velocidade de abertura de bolsas rápidas, abertura estável, aumento de 20% na eficiência de moldagem e frequência de manutenção de tempo de inatividade reduzida.

Sistema completo de acionamento por servo: controle preciso do processo de fabricação de bolsas, ajuste automático de tensão, para garantir que o corpo da bolsa seja plano e sem rugas.

Sistema de correção de desvio inteligente: Usando o dispositivo de correção de desvio BST/pínce alemão, erro ≤ ± 3 mm, transmissão de bobina estável e taxa reduzida de sucata.

2. Configuração internacional, garantia de qualidade

Sistema elétrico: Schneider plc, sensor Panasonic/Omron, tela de toque de Taiwan Weilun, interface de operação simples, suporta o monitoramento em tempo real e o ajuste dos parâmetros.

Peças mecânicas: Redutor do Servo de Shimpo Japão, Alemanha KTR Acoplamento, componentes pneumáticos SMC/Festo, para garantir uma operação estável a longo prazo do equipamento.

ROLAMENTOS E TRANSMISSÃO: ROLAMENTOS NSK/NTN, CELOS DE TRANTO DE AMERICANOS AMERICANOS, Resistente ao desgaste e resistente à pressão, prolongam a vida útil do equipamento.

3. economia de custos, produção verde

Tecnologia de laminação de lado único: reduza a largura da sobreposição, combinada com o processo de revestimento de alta precisão, cada 500 sacos produzidos pode economizar 1 dólar americano de matérias-primas.

Projeto de baixo consumo de energia: capacidade instalada 150kW, o consumo de ar comprimido é de apenas 3m³/min, a água de resfriamento é reciclada para reduzir o consumo abrangente de energia.

4. Adaptação flexível, amplamente aplicável

Compatibilidade de material forte: suporta tecido de base PP/PE (50-80g/m²), peso de laminação 18-30g/m² e é adequado para sacos de cimento de 25-50 kg, sacos químicos e outras especificações.

Mudança rápida: Dispositivo de fatia de faca circular e função de ajuste manual, a comutação de parâmetros pode ser concluída em 30 segundos para atender às pequenas necessidades de personalização em lote.

Parâmetros técnicos de relance

| Projeto | Parâmetros |

| Velocidade de produção | 110-130 peças/minuto |

| Capacidade de bolsa | 25kg-50kg (cimento/materiais químicos) |

| Precisão do peso da bolsa | 75g ± 2g |

| Peso laminado | 18-30g/m² |

| Largura do tecido base | 1000-1500mm (ajustável) |

| Capacidade de instalação | 150kW |

| Tamanho do equipamento | 11m (comprimento) × 7,5m (largura) × 2,5m (altura) |

| Peso completo da máquina | 16 toneladas |

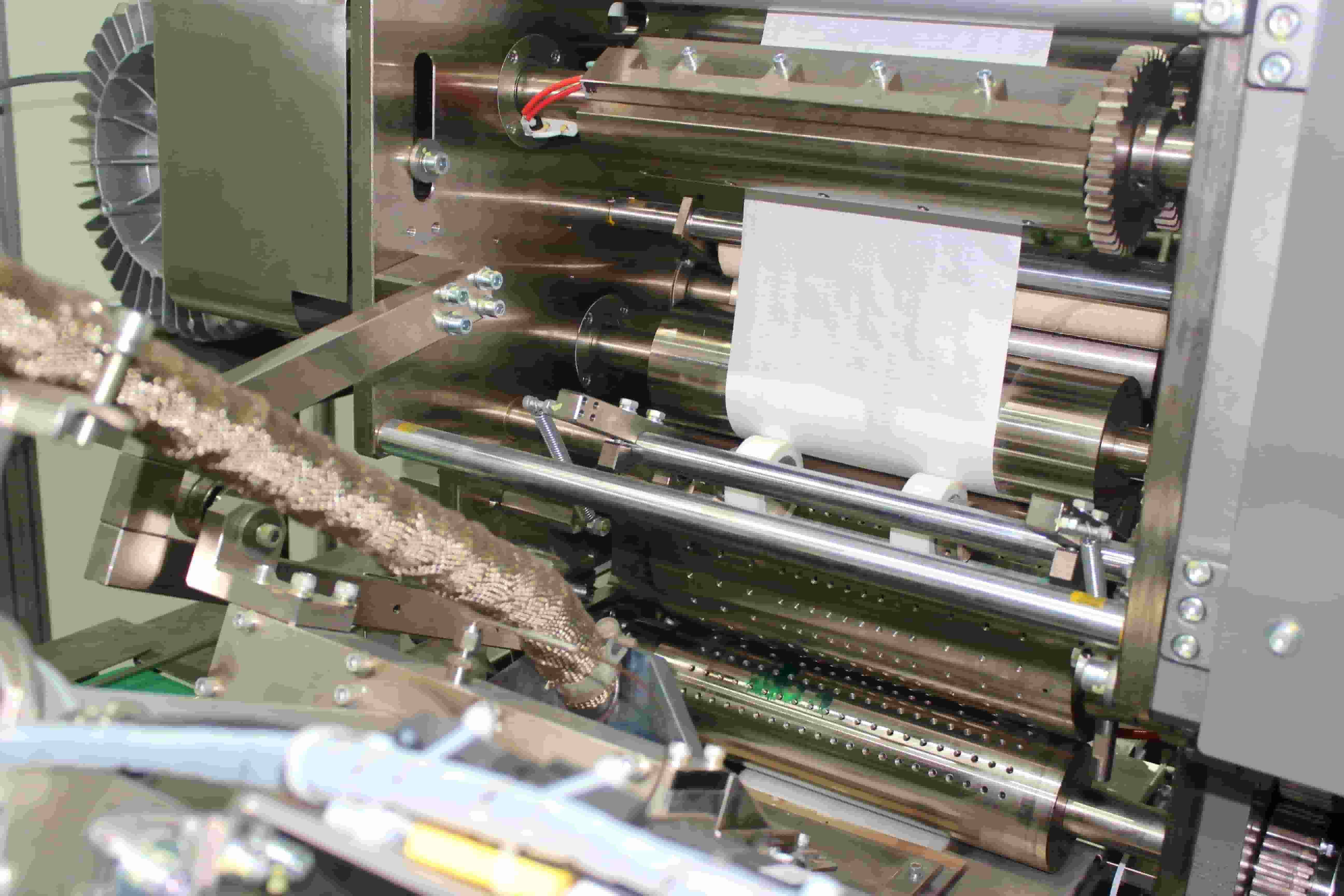

Configuração e processo do núcleo

Processo de produção totalmente automatizado

Alimentação → Controle de tensão → perfuração → Soldagem → Corte de bolsa → empilhamento: todo o processo está conectado perfeitamente, suportando uma partida e parada de um botão.

Dispositivo de alimentação sem eixo hidráulico: diâmetro máximo de rolagem 1500 mm, portador de carga 1200 kg, adequado para rolos de mãe super grande.

1. Revestimento de precisão e impressão

Uniformidade do revestimento: resistência à casca ≥3N/30mm (nacional nacional GB/T8947-1998), resíduos de borda ≤5 mm, reduzindo o desperdício.

Impressão de alta precisão: desvio de posicionamento da marcação de cores ≤20 mm, suporta a impressão multicolorida, atenda aos requisitos do logotipo da marca.

2. Sistema de controle inteligente

Interface de interação humana-máquina: A tela de toque Weilun exibe dados de produção em tempo real, alarme de falha automático, fácil de operar.

Três anos de atualização gratuita: o sistema de controle eletrônico é continuamente otimizado e compatível com os futuros requisitos de processo.

Cenários aplicáveis

Cimento e materiais de construção Indústria: sacos de cimento pesados de 25 a 50 kg e sacos de gesso.

Produtos químicos e minerais: sacos de embalagem de matéria-prima à prova de umidade e à prova de vazamentos.

Alimentos e agricultura: sacos de armazenamento de grãos, sacos de embalagem de sementes.

Por que escolher FK008-ⅲ?

Capacidade de produção de alta eficiência: 130 peças/minuto de produção de alta velocidade, a capacidade de produção anual aumentou mais de 30%.

Perda ultra-baixa: A taxa de utilização da matéria-prima é tão alta quanto 98%e a taxa de sucata é inferior a 0,5%.

Serviço pós-venda sem preocupações: instalação e treinamento em equipe profissional, atualização de controle eletrônico gratuito de três anos e suporte técnico ao longo da vida.

FK008-ⅲ A máquina de fazer bolsas de válvula totalmente automática leva a tecnologia inovadora, a qualidade internacional e a inteligência como núcleo, fornecendo às empresas uma solução única, de matérias-primas a sacolas. Seja a produção em larga escala ou as necessidades personalizadas, esta máquina automática de fabricação de bolsas de válvula inferior em bloco pode ajudá-lo a aproveitar a oportunidade de mercado com excelente desempenho e confiabilidade. Consulte agora para iniciar uma nova era de fabricação de bolsas eficientes!