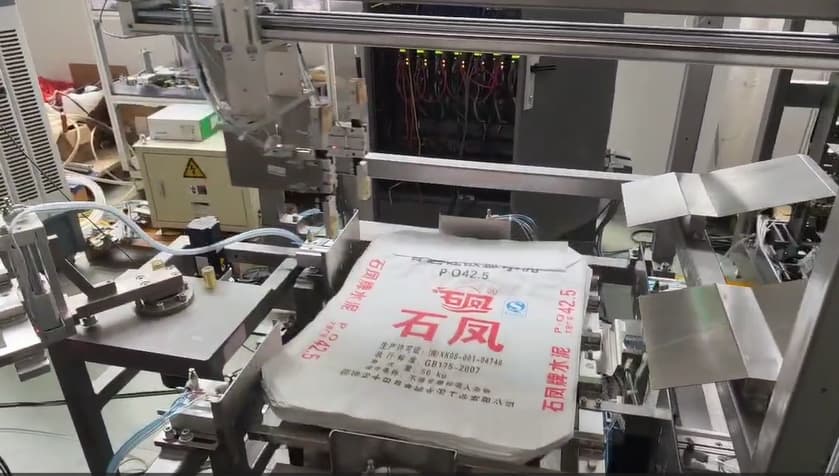

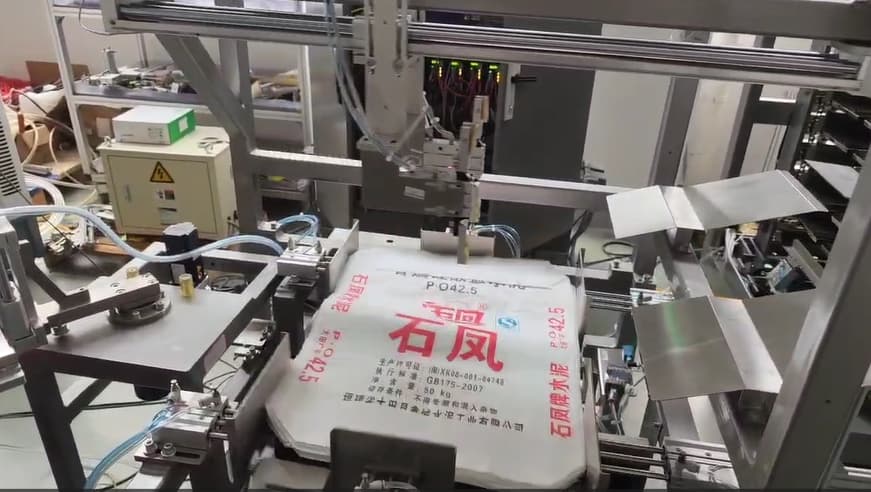

A máquina de inserção de sacos de cimento totalmente automática do grupo Gachn é um equipamento eficiente e inteligente projetado para linhas de produção de cimento, integrando automação, alta precisão e alta estabilidade.

Nome do produto :

Cement Bag Pro-InsertorItem nº :

GC-850-6SPedido (quantidade mínima) :

1Pagamento :

30% advance payment, 70% balance before shipment or negotiableOrigem do Produto :

xiamen,chinaPorto de embarque :

XIAMEN or Or according to your needsTempo de espera :

3 monthsInsersor de Saco de Cimento Pro

A máquina de inserção de sacos de cimento totalmente automática do Grupo Gachn é um equipamento eficiente e inteligente projetado para linhas de produção de cimento, integrando automação, alta precisão e alta estabilidade. Por meio de tecnologia avançada de servocontrole e sistemas inteligentes, o equipamento pode substituir completamente as operações manuais tradicionais, melhorar significativamente a eficiência da embalagem, reduzir os danos causados pela poluição por poeira aos funcionários e ajudar as empresas de cimento a alcançar uma produção sustentável e eficiente.

1. Principais vantagens técnicas

Processo totalmente automatizado

Realize a automação de todo o processo, desde a classificação de sacos, empurramento de sacos, abertura de sacos até a inserção de sacos, com uma taxa de sucesso única de inserção de sacos de ≥99% e um aumento na capacidade de produção de mais de 30%.

Equipado com sensores inteligentes e servomotores, ele controla com precisão a trajetória do movimento para garantir que os sacos de embalagem estejam intactos e que o ensacamento seja preciso.

Design modular inteligente

Peças de classificação de sacos: adote tecnologias de levantamento e suporte de sacos, agitação de sacos e batidas de sacos para reduzir o atrito entre os sacos e garantir o empilhamento organizado dos mesmos.

Peças de abertura do saco: O sistema de ventosa e gancho com curvatura adaptável da superfície do saco suporta monitoramento de pressão de vácuo em tempo real, e a estabilidade da abertura do saco atinge o nível líder do setor.

Peças de inserção de saco: componentes de fixação de saco servoacionados, que podem ajustar flexivelmente a curva de movimento e se adaptar a uma variedade de especificações de embalagem.

Alta compatibilidade e flexibilidade

A capacidade do compartimento de sacos pode ser personalizada (plataforma de cache padrão de 4 metros, acomodando 500 sacos), suportando sacos de diferentes tamanhos (comprimento × largura × altura: 6900 × 4700 × 2050 mm).

A parte inferior do equipamento é equipada com um dispositivo de ajuste horizontal para se adaptar ao layout de vários cenários de produção.

Configuração internacional de primeira classe

Sistema elétrico: Controladores e componentes de segurança Schneider, Omron e outras marcas para garantir uma operação estável e confiável.

Peças mecânicas: redutor Xinbao do Japão, acoplamento KTR da Alemanha, trilho-guia HIWIN de Taiwan, etc., para garantir longa vida útil e baixa taxa de falhas do equipamento.

2. Perspectivas de mercado e valor do investimento

A demanda da indústria aumenta

O setor global da construção civil está se desenvolvendo rapidamente e a demanda por cimento continua crescendo. A previsão é de que o mercado global de cimento ultrapasse US$ 46,85 bilhões em 2029, impulsionando a expansão simultânea do mercado de insersores de sacos.

Com a aceleração da abertura do comércio internacional, a demanda por equipamentos de automação em mercados externos aumentou significativamente, criando amplo espaço para exportação de produtos.

Redução significativa de custos e aumento de eficiência

A produção totalmente automatizada pode economizar mais de 80% dos custos de mão de obra, ao mesmo tempo em que reduz o desperdício de material e reduz os custos abrangentes em 20% a 30%.

A vida útil do equipamento é superior a 10 anos, com baixos custos de manutenção e um curto ciclo de retorno do investimento.

Vantagens competitivas excepcionais

Na acirrada competição de mercado, o inseridor de sacolas do grupo Gachn se destaca por sua alta precisão, design inteligente e modular, ajudando as empresas a melhorar sua imagem de marca e valor agregado ao produto.

Por meio da inovação tecnológica e otimização do atendimento ao cliente, a empresa ajuda as empresas de cimento a estabelecer padrões no setor em diversas dimensões, como proteção ambiental, eficiência e qualidade.

3. Visão geral dos parâmetros técnicos

| Projeto | Especificações |

| Tamanho da máquina | C5,5 m × L3,0 m × A2,2 m (layout personalizável) |

| Potência da máquina | Cerca de 10KW (fonte de alimentação: 3Ph 380Vac±5%, 50Hz) |

| Requisitos da fonte de ar | Pressão de ar ≥0,6 MPa, tanque de gás padrão de 20 L |

| Tipo de bolsa aplicável | Vários tamanhos (suporte a comprimento de plataforma de cache personalizado) |

| Marca do componente principal | Marcas internacionais como Schneider, Omron, Xinbao, HIWIN, etc. |

4. Cenários de aplicação

Linha de produção de cimento: conexão perfeita com equipamento de enchimento para atingir operação contínua de alta velocidade.

Centro de armazenagem e logística: adequado para paletização e transporte automatizados de cimento ensacado.

Projetos internacionais: atendemos aos rigorosos padrões de equipamentos de alta precisão na Europa, América, Sudeste Asiático e outras regiões.

A inseridora de sacos de cimento totalmente automática do Grupo Gachn conta com tecnologia de ponta, alta eficiência e confiabilidade, oferecendo soluções inteligentes de atualização para empresas cimenteiras globais. Investir no Grupo Gachn não se resume apenas à escolha de um equipamento, mas também a um layout estratégico para aproveitar as futuras oportunidades de mercado!