Gachn Group In-Cargo Loader: 60cm Low-Position Bag Dropping + 3D Scanning, Completely Solves Non-Standard Vehicle Adaptation Dilemma

In the building materials, chemical and other industries, non-standard vehicles such as high-sided trucks, flatbed trucks and modified agricultural vehicles account for over 60%. Traditional loading solutions either "can’t load" or "load messily" — manual loading requires 3-5 workers to collaborate, with an efficiency of only 30 tons per hour, accompanied by explosive dust leakage; robotic arm solutions can’t adapt to side rail heights, and skewed stacking leads to a cargo damage rate of over 5%. Gachn Group’s world-first "in-cargo" intelligent loader, equipped with 60cm low-position bag dropping and 3D radar scanning technology, completely ends the predicament of high-sided truck loading!

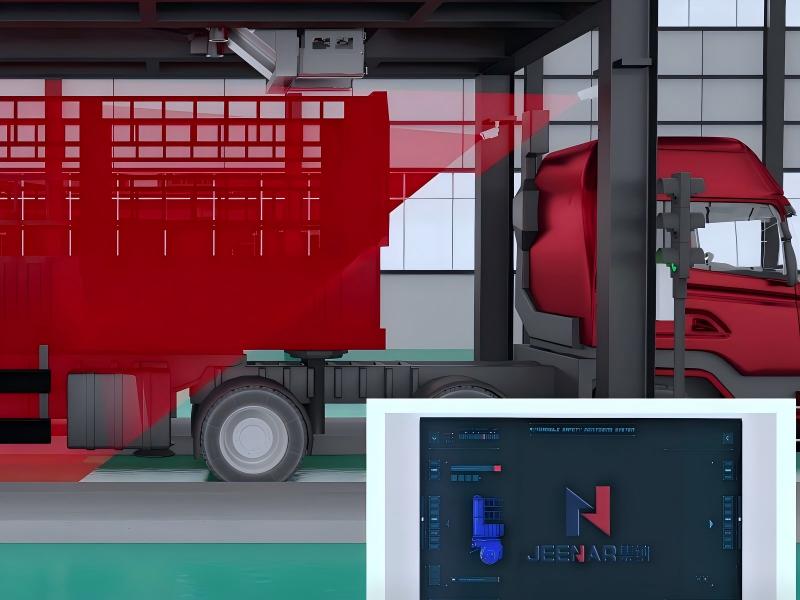

1. 3D Radar Scanning + Intelligent Modeling, Locking Compartment Contours in 3 Seconds: Equipped with high-precision 3D radar, the equipment can quickly identify various compartments with lengths of 0.7-17.5 meters, widths of 1.4-3.0 meters and maximum heights of 4.0 meters, automatically generating loading layout plans. Whether it’s high-sided trucks, extra-long flatbeds or modified agricultural vehicles, it can achieve precise matching, increasing space utilization rate to 95%.

2. 60cm Low-Position Bag Dropping, Dual Guarantee of Dust-Free and Low Loss: The machine head operates directly inside the compartment, with a bag dropping height of only 60cm. Compared with traditional high-position bag dropping, dust is reduced by 90%. Combined with the dust collection system, the dust concentration in the working environment is <0.5mg/m³; the gentle stacking design keeps the bag breakage rate below 0.1%, saving enterprises over 100,000 yuan in material loss annually.

· Loading Efficiency: The loading speed for high-sided trucks reaches 95-120 tons per hour, 3 times higher than manual loading. One piece of equipment replaces 3-5 porters. After application at Jinniu Cement Plant, the loading efficiency of high-sided trucks jumped from 40 tons per hour to 100 tons per hour.

· Adaptability: Compatible with horizontal, vertical and mixed stacking, supporting various specifications such as 50kg/ton bags, meeting the loading needs of different materials in building materials, chemical industry, mineral powder and other fields.

· Maintenance Cost: Modular design + core components from Schneider and Panasonic, with mean time between failures (MTBF) exceeding 8000 hours, and annual maintenance cost only 1/3 of that of traditional stacking head solutions.

With 8 years of deep industry experience, Gachn Group’s in-cargo loader has become the preferred choice for high-sided truck loading among over 300 enterprises, relying on three core advantages: "scenario adaptation + intelligent efficiency + environmental compliance". From installation and commissioning to personnel training, we provide 24-hour rapid response service, and the national service network ensures the efficient operation of equipment for life.

Say goodbye to the pain points of difficult high-sided truck loading, heavy dust and high costs. Gachn Group’s in-cargo intelligent loader makes loading of non-standard vehicles "one-click completion"! Welcome to consult and get exclusive loading solutions.