Máquina de bolsa de válvula automática inovadora para sacos adstar com o rolo flutuante

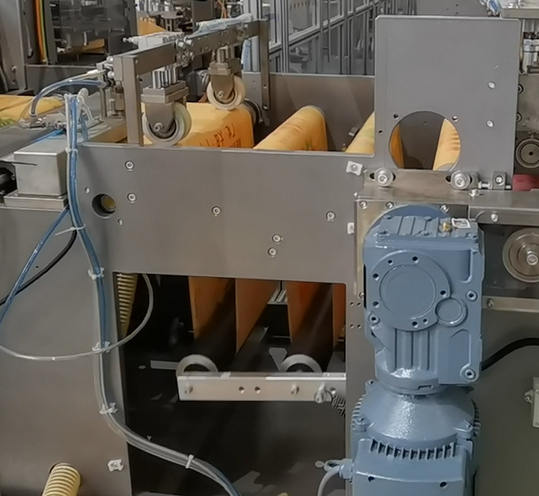

Durante o estágio de fabricação de bolsas da máquina de fabricação de bolsas de válvula de grupo Gachn, o rolo flutuante é usado para controlar a tensão do material do filme para garantir a estabilidade e a qualidade do processo de fabricação de bolsas.

Nome do produto :

Innovative Automatic Valve Bag Machine For Adstar Bags With The Floating RollerItem nº :

FK008-IIPedido (quantidade mínima) :

1Pagamento :

30% advance payment, 70% balance before shipment or negotiableOrigem do Produto :

xiamen,chinaPorto de embarque :

XIAMEN or Or according to your needsTempo de espera :

3 monthsMáquina de bolsa de válvula automática inovadora para sacos adstar com o rolo flutuante

Durante o estágio de fabricação de bolsas do grupo Gachn Group Automatic PP Tecla Machine onde comprar, o rolo flutuante é usado para controlar a tensão do material do filme para garantir a estabilidade e a qualidade do processo de fabricação de bolsas. Se a tensão da saída do fio pela máquina de desenho de arame não atender ao padrão, ela afetará diretamente o desempenho da tensão da máquina de fabricação de bolsas ao produzir sacos de válvula, o que pode causar problemas como sacos quebrados e sacos de vazamento.

No processo de desenhar o fio pela máquina de desenho de arame, a tensão instável ou abaixo do padrão da saída do fio pela máquina de desenho de arame afetará diretamente a estabilidade e a qualidade da máquina de fazer a bolsa durante o processo de produção. Muita ou pouca tensão pode causar deformação e quebra do material do filme durante o processo de fabricação de bolsas. Embora a fabricação automática automática de máquinas de saco na China não ajuste diretamente a tensão da máquina de desenho de arame, a máquina de fabricação de bolsas pode determinar os problemas de tensão através do rolo flutuante durante o processo de fabricação de bolsas, que pode ser alimentado de volta à máquina de desenho de arame para solicitar que possa haver problemas em sua produção e ajuste ou manutenção. Verifique se o processo de fabricação de bolsas não deixará de obter controle estável de tensão, o que pode causar problemas como tamanho de bolsa instável, forma irregular e aperto desigual. Em casos graves, pode até haver problemas de qualidade, como sacolas quebradas e sacolas com vazamento.

Para esse fim, os rolos flutuantes do Gachn Group podem garantir que os materiais de arame e filme sejam tensionados de forma estável durante o processo de produção e fabricação de bolsas, melhorando assim a qualidade e a consistência do produto.

Melhorar a eficiência da produção: O controle estável de tensão pode reduzir a taxa de falha e o tempo de inatividade no processo de produção, melhorando assim a eficiência da produção.

Conexão do processo: Em todo o processo de produção de linhas de sacos de válvulas, a máquina de desenho de arame e a máquina de fazer saco de válvulas precisam cooperar de perto. Após a máquina de desenho de arame processar as matérias -primas em filmes ou fios que atendem aos requisitos, esses materiais serão enviados para a máquina de fabricação de bolsas de válvulas para a formação subsequente, a vedação, o corte e outros processos. Portanto, a eficiência da produção e a qualidade do produto da máquina de desenho de arame afetam diretamente a eficiência da produção e a qualidade do produto da máquina de fabricação de bolsas de válvula.

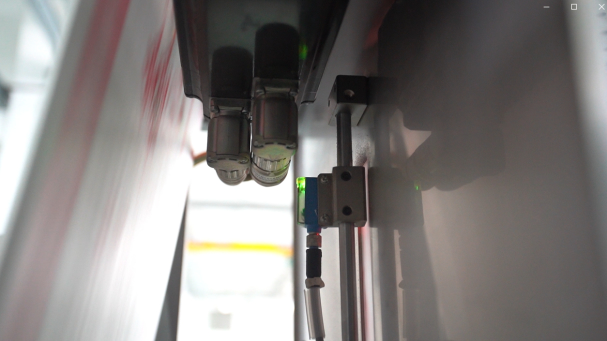

Sinergia técnica: Com o desenvolvimento contínuo da indústria de sacolas de válvulas, a tecnologia da máquina de fabricação automática de bolsas de válvulas do Gachn Group para máquinas de venda e desenho de arame também está melhorando constantemente. O Gachngroup exige melhorar a eficiência da produção, reduzindo os custos e melhorando a qualidade do produto como fatores -chave. O dispositivo de tração de desenrolamento é adotado e o motor servo é usado para controle separado. O cilindro manual controlado pela válvula é usado para realizar a operação conveniente da abertura e fechamento do rolo de fixação e a rosca de material. O mecanismo de transferência é equipado com uma haste de tensão flutuante com tensão ajustável, que mantém a tensão constante do rolo de pano estável durante a operação para se adaptar à estabilidade da produção de bolsas de válvula para vários materiais de desenho de arame.

Dispositivo de fabricação de bolsas: O Gachn Group possui dois métodos de fabricação de bolsas, marca de cor e comprimento fixo, no dispositivo de fabricação de bolsas, incluindo puxar, marca de cores e corte traseiro. Ele pode ser definido na tela de toque para garantir a precisão da produção de bolsas.

Dispositivo de transmissão: O dispositivo de formação de fundo da bolsa consiste em um dispositivo de formação triangular e um transportador de correia; No dispositivo de formação triangular, dois conjuntos de placas triangulares funcionam, por sua vez, para garantir uma formação eficiente e estável, e a largura da placa é ajustável para se adaptar a sacos de tamanhos diferentes; O transportador da correia garante que a boca do saco esteja completamente fechada. A unidade de transporte adota uma bolsa de rastreador pressionando para tornar a bolsa descarregar mais suavemente. Esse design pode liberar e empilhar um certo número de sacolas por vez, e o número pode ser definido na tela; O transporte adota um motor servo como dispositivo de acionamento, e a distância de transmissão pode ser definida na tela. Torne o equipamento preciso e estável, garantindo que a velocidade de inicialização do cliente seja estável, alta velocidade, bela e alta resistência de solda.

A máquina de fabricação de saco de válvulas e a máquina de desenho de arame são inseparáveis no processo de produção de bolsas de válvula. A máquina de desenho de arame fornece matérias -primas para a máquina de fabricação de bolsas de válvula, e a máquina de fazer a saco de válvulas usa essas matérias -primas para produzir com eficiência e precisão sacos de válvula que atendam aos requisitos. A estreita cooperação e sinergia técnica entre os dois são de grande importância para melhorar a eficiência da produção e garantir a qualidade do produto. Portanto, no processo de produção de bolsas de válvulas, as máquinas de fabricação de bolsas de válvula de alta qualidade estão relacionadas à pesquisa e desenvolvimento técnico e otimização de processos para promover o desenvolvimento sustentável e saudável da indústria de embalagens.