Máquina de bolsa de válvula automática inovadora para sacos adstar

Na era de hoje de buscar eficiência e economia de custos, as máquinas de fazer bolsas de válvula se destacam na indústria de embalagens com suas vantagens únicas e se tornam o equipamento preferido para materiais de embalagem de muitos fabricantes.

Nome do produto :

Innovative Automatic Valve Bag Machine For Adstar BagsItem nº :

FK008-IIPedido (quantidade mínima) :

1Pagamento :

30% advance payment, 70% balance before shipment or negotiableOrigem do Produto :

xiamen,chinaPorto de embarque :

XIAMEN or Or according to your needsTempo de espera :

3 monthsMáquina de bolsa de válvula automática inovadora para sacos adstar

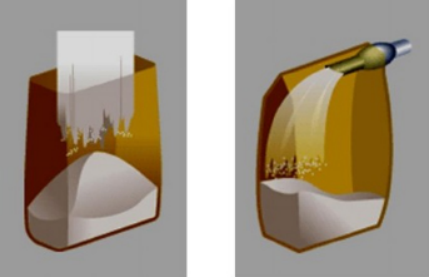

Na era de hoje de buscar eficiência e economia de custos, as máquinas de fazer bolsas de válvula se destacam na indústria de embalagens com suas vantagens únicas e se tornam o equipamento preferido para materiais de embalagem de muitos fabricantes. Os sacos de válvula, com seu design exclusivo da porta da válvula e desempenho de vedação, não apenas melhoram a eficiência do enchimento, mas também reduzem o processo de costura manual, tornando todo o processo de embalagem mais suave e mais eficiente.

A adaptabilidade dos sacos de válvulas é muito ampla, cobrindo vários setores. Na indústria química, é usado para empacotar fertilizantes, pigmentos, partículas de plástico, etc.; Na indústria de alimentos, é usado para empacotar matérias -primas alimentares, como farinha, açúcar e sal; Além disso, nos materiais de construção e indústrias farmacêuticas, os sacos de válvulas também desempenham um papel importante. Essa ampla adaptabilidade faz com que a máquina de válvula composta composta de papel faça um equipamento de embalagem versátil.

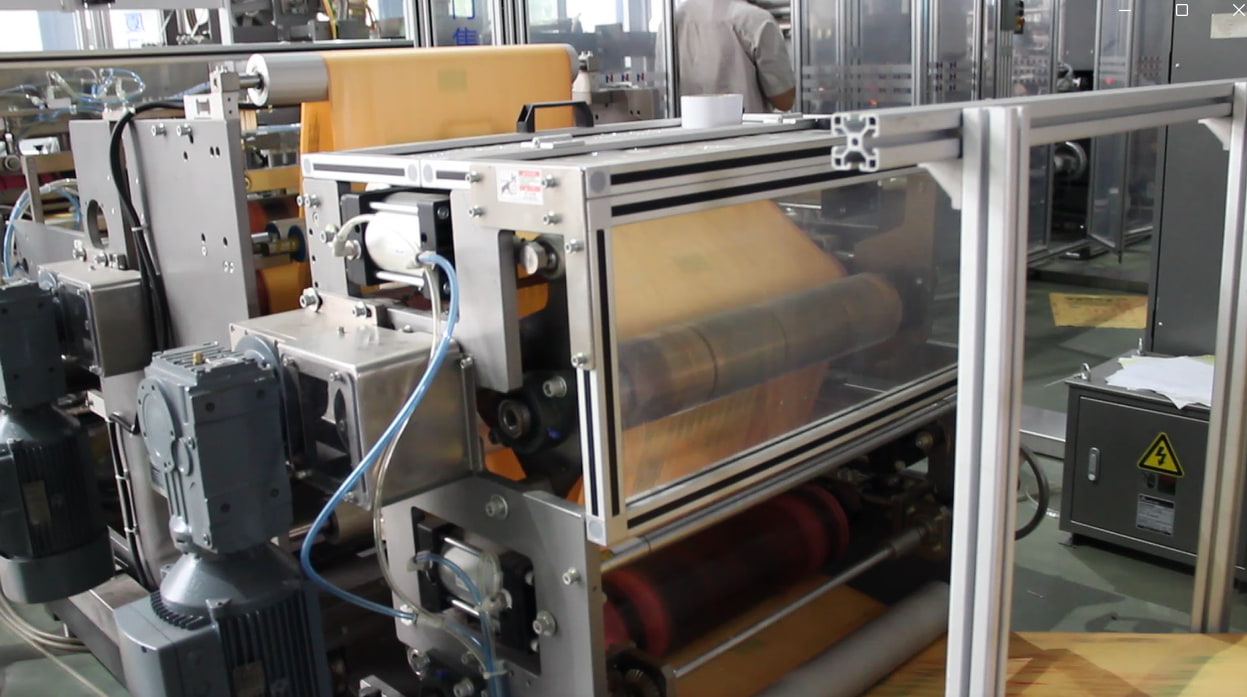

Alto grau de automação: é uma grande vantagem da máquina de fabricação de saco composta plástica em papel. Desde a alimentação de matérias -primas até a saída de sacos acabados, todo o processo de produção pode ser concluído automaticamente, reduzindo bastante a intervenção manual e melhorando a eficiência da produção. Esse processo automatizado não apenas reduz os custos de mão -de -obra, mas também melhora a precisão e a consistência da embalagem.

Personalização diversificada: Uma característica notável da máquina de fabricação de saco de válvulas do Gachn Group. De acordo com diferentes características do produto e requisitos de embalagem, a máquina de fabricação de bolsas pode ajustar o tipo de bolsa, tamanho e padrão de impressão para atender às diversas necessidades de embalagem. Essa flexibilidade permite que o saco de válvulas se adapte aos requisitos de diferentes mercados e clientes e forneça soluções de embalagem personalizadas para produtos.

Em termos de facilidade de operação: A máquina de fabricação de saco de válvulas do Gachn Group também funciona muito bem. Embora integra muitas funções complexas, a interface de operação geralmente é projetada para ser intuitiva e fácil de usar, para que os operadores possam começar rapidamente, mesmo que sejam não profissionais. Isso reduz os requisitos de habilidade para os operadores e melhora a eficiência geral da linha de produção.

Excelentes características da máquina de fabricação de bolsas de válvula do Gachn Group: O Gachn Group fornece a você um estável, confiável, ambientalmente amigável, economizando energia e altamente integrado, atualizando continuamente o equipamento.

Máquina de fabricação de bolsas de válvula de alta qualidade: A máquina de fabricação de válvula composta de papel-plástica do grupo Gachn mostra boa estabilidade e confiabilidade na operação de longo prazo. Durante o processo de produção, o equipamento pode produzir contínuo e estável os sacos de válvula de alta qualidade e, através do sistema completo de controle de servo, a interrupção da produção causada pela falha do equipamento é bastante reduzida. Essa estabilidade não apenas melhora a eficiência da produção, mas também reduz os custos de taxa de falhas e manutenção, criando maiores benefícios econômicos para as empresas.

Máquina de fabricação de bolsas de válvula de grupo Gachn: Os requisitos de conservação de energia e redução de emissões são totalmente considerados no projeto. Ao usar menos energia e matérias -primas, o equipamento reduz os custos de produção e reduz o impacto no meio ambiente. Esse conceito de design ambientalmente amigável e de economia de energia está de acordo com a atual busca global do desenvolvimento sustentável, que ajuda as empresas a alcançar a produção verde e melhorar sua imagem de marca.

Em termos de expansão funcional, a máquina de fabricação de bolsas de válvula de grupo Gachn também tem um bom desempenho. Com as mudanças contínuas na demanda do mercado, as empresas podem precisar ajustar os tipos de bolsas, tamanhos ou adicionar novas funções. Estruturas modulares, como a inspeção visual da IA, combinadas com máquinas de fazer bolsas de válvula, podem facilmente alcançar esses ajustes para atender às diversas necessidades das empresas. Essa flexibilidade permite que as empresas se adaptem rapidamente às mudanças no mercado e mantenham sua vantagem competitiva.